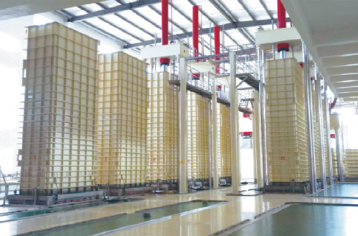

Koji Making Disc Machine

- yutong

Koji Making Disc Machine Equipment Features:●The entire production process is mechanized, and the flipping and discharging of materials during feeding and cultivation are all operated by machinery. Throughout the process, people do not directly contact materials to avoid human contamination.●High degree of automation, with PLC programming control for temperature, humidity, and air volume control. Working parameters can be modified according to different materials and automatically saved for easy traceability and reference.●Koji Making Disc MachineThe intelligent control system for koji material minimizes energy consumption while ensuring material quality.●The operation is simple, with two operation modes to choose from: button and touch screen, making the koji process safer and more reliable.●High production accuracy, flat curved discs, and minimal material leakage; Discharging and flipping are thorough, with no large pieces of material. After flipping, the material surface is flat and free of dead corners.Koji Making Disc Machine Basic parameters of the host:

koji making machine

- yutong

koji-making machine:■ High degree of automation: Aiming to achieve unmanned management: air volume, wind pressure, temperature, humidity and other koji-making factors are automatically controlled and recorded by the koji-making program.■ High degree of humanization: PLC programming control, touch screen operation, so that the parameters of the koji making program can be modified and saved (up to 10 sets of koji making programs).■ The disc body is made with high precision: less material leakage, there is basically no residual material on the disc body after the bending, and the bending is complete.■ Highly digital display of incoming and outgoing materials: making incoming and outgoing materials more convenient.■ Open center column design: thorough cleaning and easy maintenance.■ Fans and disk drives are all controlled by frequency converters: energy saving and automatic operation.■ Overall beautiful and delicate.Basic parameters of the host:SpecificatiDisc diameter(mm)Disc diameter(m2)Material layer thickness(mm)Power(kw)External dimensions(mm)ZQY-6600028≤4002612000*10000*4220ZQY-7$700038≤4005014000*11000*4220ZQY-9$900064≤4006017000*14000*4520ZQY-12$12000113≤4009019000*16000*4520ZQY-13$13000132≤40012020000*17000*4520ZQY-16$16000196≤60017525000*20000*5000ZQY-20$20000307≤60020030000*25000*5000

vinegar fermentation tank(Strain culture tank)

- yutong

Equipment features:Vinegar Fermentation Tank(Strain culture tank) the entire production process is mechanized, and the flipping and discharging of materials during feeding and cultivation are all operated by machinery. Throughout the entire process, people and materials are not directly connectedTouch to avoid human contamination.High degree of automation, with PLC programming control for temperature, humidity, and air volume control. Working parameters can be modified according to different materials and automatically saved for easy traceabilityReference.The intelligent koji control system minimizes energy consumption while ensuring material quality.The operation is simple, with two operation modes to choose from: button and touch screen, making the bending process safer and more reliable.High production accuracy, smooth curved surface, and minimal material leakage; Discharging and flipping are thorough, with no large pieces of material. After flipping, the material surface is flat and free of dead corners.Basic parameters of the host:SpecificatiDisc diameter(mm)Disc diameter(m2)Material layer thickness(mm)Power(kw)External dimensions(mm)ZQY-6600028≤4002612000*10000*4220ZQY-7$700038≤4005014000*11000*4220ZQY-9$900064≤4006017000*14000*4520ZQY-12$12000113≤4009019000*16000*4520ZQY-13$13000132≤40012020000*17000*4520ZQY-16$16000196≤60017525000*20000*5000ZQY-20$20000307≤60020030000*25000*5000

Soy sauce brewing equipment

- yutong

Soy sauce brewing equipment has achieved full mechanization. From feeding, to turning over during the cultivation process, and to discharging, all are automatically completed by machinery. There is zero direct contact between people and materials throughout the whole process, effectively eliminating artificial pollution and ensuring product quality.

Rotary Koji Making Machine

- yutong

This utility model discloses a feeding device for a Rotary Koji Making Machine, comprising a feeding platform arranged above the rotating disc, wherein a moving conveyor is arranged on the feeding platform that can move radially back and forth along the rotating disc. The moving conveyor is equipped with a conveyor belt that matches the feeding port of the rotating disc bending machine, and also includes a controller that can adjust the moving speed of the moving conveyor and the conveying speed of the conveyor belt separately. During the working process, the speed of the moving conveyor and the conveying speed of the conveyor belt are variable speed controlled by the controller to achieve precise control of the amount of material falling, ensuring a constant amount of material on each section of the conveyor belt, thereby effectively improving the rotation. The flatness of the material after the discharge of the Rotary Koji Making Machine ensures the smooth implementation of subsequent process operations

Automatic Disc Koji Making machine

- yutong

Automatic Disc Koji Making machine features:Centralized integrated design, achieving expanded production capacity within limited space, 11-17 tons of mixture/batch;Set up control system modules, customize operation interfaces, and provide various functions required by operators;Authentic materials, except for accessories such as rotation and motors, all equipment components are made of stainless steel 304 material;A precise air conditioning system provides the growth conditions for preserving Aspergillus oryzae, ensuring a rich enzyme system and upper enzyme activity;A comprehensive CIP cleaning system that can automatically clean with just one click operation and ensure the cleaning effect, reduce the number of mold forming bacteria, and improve the quality of soy sauce;A good spore powder dispersion prevention system reduces environmental pollution and loss of effective substances;Automatic Disc Koji Making machine featuresThis Automatic Disc Koji-Making machine has been carefully designed, with each batch of materials weighing up to 15 tons, allowing for greater capacity in limited space.The various functions required by operators can be provided through automotive system modules and intelligent interfaces.All components of the equipment, except for the spindle, motor, and other accessories, are made of stainless steel material.The precise air conditioning system inside the machine ensures suitable conditions for microbial reproduction and reproduction. In addition, a rich variety of highly active enzymes can also be obtained.The improved CIP cleaning program of this machine can automatically clean, reducing the number of contaminating microorganisms, and improving the quality of soy sauce due to environmental cleanliness.A good system can prevent the spread of Aspergillus oryzae spores inside the machine, thereby reducing environmental pollution and loss of effective substances.