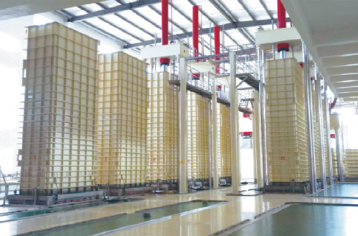

Automatic Disc Koji Making machine

- yutong

Automatic Disc Koji Making machine features:Centralized integrated design, achieving expanded production capacity within limited space, 11-17 tons of mixture/batch;Set up control system modules, customize operation interfaces, and provide various functions required by operators;Authentic materials, except for accessories such as rotation and motors, all equipment components are made of stainless steel 304 material;A precise air conditioning system provides the growth conditions for preserving Aspergillus oryzae, ensuring a rich enzyme system and upper enzyme activity;A comprehensive CIP cleaning system that can automatically clean with just one click operation and ensure the cleaning effect, reduce the number of mold forming bacteria, and improve the quality of soy sauce;A good spore powder dispersion prevention system reduces environmental pollution and loss of effective substances;Automatic Disc Koji Making machine featuresThis Automatic Disc Koji-Making machine has been carefully designed, with each batch of materials weighing up to 15 tons, allowing for greater capacity in limited space.The various functions required by operators can be provided through automotive system modules and intelligent interfaces.All components of the equipment, except for the spindle, motor, and other accessories, are made of stainless steel material.The precise air conditioning system inside the machine ensures suitable conditions for microbial reproduction and reproduction. In addition, a rich variety of highly active enzymes can also be obtained.The improved CIP cleaning program of this machine can automatically clean, reducing the number of contaminating microorganisms, and improving the quality of soy sauce due to environmental cleanliness.A good system can prevent the spread of Aspergillus oryzae spores inside the machine, thereby reducing environmental pollution and loss of effective substances.

Continuous Pasta Cooker

- yutong

We produce continuous Continuous Pasta Cooker and customize designs according to customer specifications.All parts are manufactured and assembled in our factory, and our technical personnel follow the customer throughout the process from specification definition to factory start-up.These machines can be powered by external steam generators, gas burners, or resistors.Our Continuous Pasta Cooker and production lines have been researched to provide the best results and minimize cleaning time. Each potential hazardous mechanical component is covered with appropriate protective measures.The lid of the steaming and cooking tank can be automatically lifted, making it convenient for cleaning and maintenance.All components in contact with food are made of AISI 304 stainless steel.Stainless steel or plastic conveyor belt; The belt speed is controlled by an electronic inverter.Automatically control water level and temperature.

Continuous Cooking Line

- yutong

The CKC series continuous cookware integrates steaming, aromatization, coloring, acid addition, mixing, and tempering.CKC.75 and CKC.120 can produce up to 750 kilograms per hour (1650 pounds per hour) or 1200 kilograms per hour (2650 pounds per hour) of sugar or sugar free hard candy.Confitech continuous hot cookware combines the advantages of plate heat exchanger technology with high automation, providing an efficient and reliable solution for high-capacity production processes.The cooking process is carried out in PHE, where the product flows into the flash evaporation chamber and releases moisture. Directly below the flash evaporation chamber, the vacuum chamber provides additional water release, while the screw extraction device drives the product into a dynamic online mixer where colors, spices, and acids are automatically mixed into the mass in a predetermined ratio.Finally, collect the quality on a stainless steel cooling strip with three independent cooling sections.Three folding plows and rollers smoothly temper and knead the material, and then directly feed it into the molding machine.The dual mixer version CKC.100D allows for simultaneous temperature adjustment of two different colors and flavors of candies.

Fried Instant Noodle Production Line

- yutong

Deep frying is the process of placing quantitatively cut dough into a frying box, and through a high-temperature oil bath, the water in the dough quickly vaporizes, forming a porous structure in the noodles and further gelatinizing the starch.The frying function of the instant noodle production line:(1) Completely gelatinize starch;(2) Dehydration;(3) Fixed shape.Specific operation: Control the transmission speed of the frying box to control the frying time. Control the front temperature, middle temperature, and back temperature of the fryer to ensure the frying effect. These are mainly achieved by adjusting the oil flow rate.The factors that affect the frying effect of instant noodle production lines:(1) Frying temperatureThe oil temperature is too low, and the dough cannot be fried thoroughly; If the temperature is too high, the dough will explode and burn. Deep frying is divided into three stages: in the low-temperature zone, the dough absorbs heat, the temperature rises, and dehydration begins; Entering the medium temperature zone, the dough begins to dehydrate significantly, and oil seeps into the noodles; The water content in the high-temperature area is basically stable and no longer dehydrates. The temperature is similar to the oil temperature. This increases the gelatinization degree of starch and causes denaturation of protein thickness.(2) Frying timeThe frying time is also an important factor affecting the frying effect. It interacts with oil temperature. If the moisture content in the dough is determined and the oil temperature is low, the frying time will be longer; High oil temperature and short frying time. The frying time is too short, and the dough is not dehydrated thoroughly, making it difficult to store; If the time is too long, the dough will bubble and fry, affecting the quality of the pastry and increasing the cost.(3) Oil levelIf the oil level is too low, the dough will dehydrate slowly, which may result in incomplete frying and fuel consumption; High oil level, increased circulation, and susceptibility to sourness. The unstable oil level has an impact on the gelatinization degree of the dough and the oil content of the product.(4) Oil qualityThe content of saturated fatty acids in fats is low, and oils are prone to rancidity. Products not only consume more oil, but are also prone to rancidity. Good quality oil not only saves fuel, but also produces high-quality fried dough. Palm oil with a melting point of 26-30 ℃ is generally used.In addition, fuel consumption and the properties of the dough itself can also have an impact on the frying effect.

Noodle Production Line

- yutong

Fast food is suitable for the needs of modern life rhythm and is deeply loved by people. Instant noodles have become the mainstream product of convenient instruments. According to relevant data statistics, the annual per capita sales of instant noodles in China are 14 packages, only one-third of Japan's and one-sixth of South Korea's, with huge consumption potential. But the competition in the instant noodle market is quite fierce, with over 90% of the market share held by a few large enterprises. Therefore, for many small and medium-sized enterprises, developing new products and occupying blank markets is the only option. The emergence of instant noodles such as instant rice noodles and non fried instant noodles has significantly changed the problem of poor taste of the original instant noodles and broken the dominance of instant noodles in non fried foods. In today's world where health will become the theme, its market will have great potential, as evidenced by the success of some convenience rice noodle and instant noodle factories. For example, instant noodle factories can use their existing sales channels to launch new products, such as Long Sao, Yu Niang, and Xiuhe rice noodles.The instant noodle production line is used to achieve the production process of assembling and conveying instant noodlesThe instant noodle production line is composed of a salt water mixer, a salt water metering device, a dual axis and dual speed dough mixer, a disc curing machine, a composite rolling machine, a multi-layer steaming machine, a block cutting and sorting machine, a frying machine, an air-cooled machine, a conveyor, etc.

Instant Noodle Processing Line

- yutong

The instant noodle production line has been upgraded for the conventional 800, 900, 1000, and 1500 models, with larger production capacity and higher efficiency. The entire production line has a daily production capacity of 120000 pieces (24 hours) to a maximum shift production of 1.8 million pieces, with a high degree of automation. The complete safety and hygiene design is suitable for large instant noodle production enterprises with a certain scale. At present, it has been applied in more than 40 countries and regions such as Germany, Czech Republic, Hong Kong, Singapore, Malaysia, Indonesia, Myanmar, Cambodia, Vietnam, Russia, Kazakhstan, Mongolia, Egypt, Brazil, Nigeria, Kenya, South Africa, etc. The instant noodle equipment adopts PLC control, with a high degree of automation. From mixing powder and noodles, rolling and arranging flowers, frying and air cooling to packaging, it basically achieves full automation. The produced instant noodles have a short rehydration time, high quality, neat noodles, adjustable oil content, and smooth and smooth texture. The flower arrangement device can be adjusted to bend or straighten, and can be used for both straight and curved surfaces. The development of a square and circular integrated instant noodle production line can achieve integrated production of square, circular, bag, and cup surfaces, which is more suitable for early testing of emerging market demands. Complete supporting packaging equipment, automatic packaging, feeding, capping, and boxing, can achieve overall linked automation operation.1. Fully automatic powder supply system/dough mixing systemThe flour is quickly transported to the dough mixer through positive pressure quantitative air, with a long transportation distance, reducing flour pollution, maintaining a clean and hygienic environment, and reducing labor intensity. Mix flour and water evenly, with dual axis, multiple stages, and multiple speeds that can be set to make the flour mix more evenly, which is beneficial for the next step of the noodle pressing process.2. New split type surface conveyorStatic maturation, uniform feeding for the tablet pressing process, continuous and uninterrupted feeding through photoelectric induction. Customized spiral crushing particles are loose and semi enclosed to retain moisture, facilitating the formation of gluten networks and facilitating cleaning.3. International new instant noodle equipment rolling machineThe formed face strip is continuously rolled into a certain thickness requirement by multiple pressure rollers, and then cut into strips by a face knife to form it. The top of the strip is automatically fed, and the tension of the face strip is automatically adjusted between different power sources. Single side synchronous adjustment is convenient, and multi-stage production is convenient for transportation and assembly, with stable operation. The international new rolling host adopts a large roller diameter with fast linear speed, pneumatic adjustment, and larger output.4. Vertical lifting water sealed multi-layer steaming machineSend the noodles that have formed ripples and are arranged in rows onto a mesh belt into a steamer, and use steam heating to gelatinize the noodles and fix the shape of the rippled surface. The overall cover of the lifting box is easy to clean, with a water sealed structure and no need to replace the sealing strip. The newly designed pipeline layout can save up to 23% energy on the entire line.5. Cutting and sorting machineThe counterweight type cutting and folding structure runs smoothly and can cooperate with the production line to achieve ultra-high cutting speed, ensuring stable and reliable box entry. You can customize square or circular pancakes with different diameters and thicknesses according to your needs. After cutting them into the box, you also need to blow and shape them before entering the frying stage.6. Lift fryerThere are observation windows on both sides of the lifting fryer, and the opening method is an upward flipping cover. The noodle box adopts a counterweight type self hanging tensioning, and the oil return from the oil pot is collected in the middle and then discharged from the side. Combined with a roller type slag filter and a fine filter, the oil circuit is recycled for energy-saving and odorless use.7. The new generation of powerful air-cooled machinesThe high-temperature fried dough is subjected to strong air cooling to quickly cool, bringing the temperature of the dough close to room temperature for easy packaging and storage. The fan can adopt either a downward blowing and upward suction type or a side inlet and upward suction type for cooling, ensuring product hygiene. The slide adopts a new type of O-shaped top surface, with a small contact surface with the surface block.